Vacuum blasting success on Piper Bravo platform

Repsol Sinopec reduced labour hours by 60% with Pinovo

The challenge: labour-intensive FM routines and safety concerns

A 2015 review of Fabric Maintenance (FM) operations on the Piper Bravo platform revealed an alarming insight: around 65% of all productive hours were spent not on blasting or coating, but on indirect tasks—scaffolding, masking, encapsulation, and abrasive cleanup. These steps not only consumed time and budget, but also raised safety concerns.

Escaping dust and abrasive posed risks to nearby safety-critical equipment and the workers themselves, especially in areas where habitats could not offer full containment.

The solution: Pinovo + rope access

In March 2016, Repsol Sinopec Resources UK launched a field trial with Pinovo’s closed-loop vacuum blasting system, integrating it with rope access to eliminate the need for scaffolding. The scope: 30 lines with localised corrosion and thinning—situated in challenging zones, including elevated and obstructed areas.

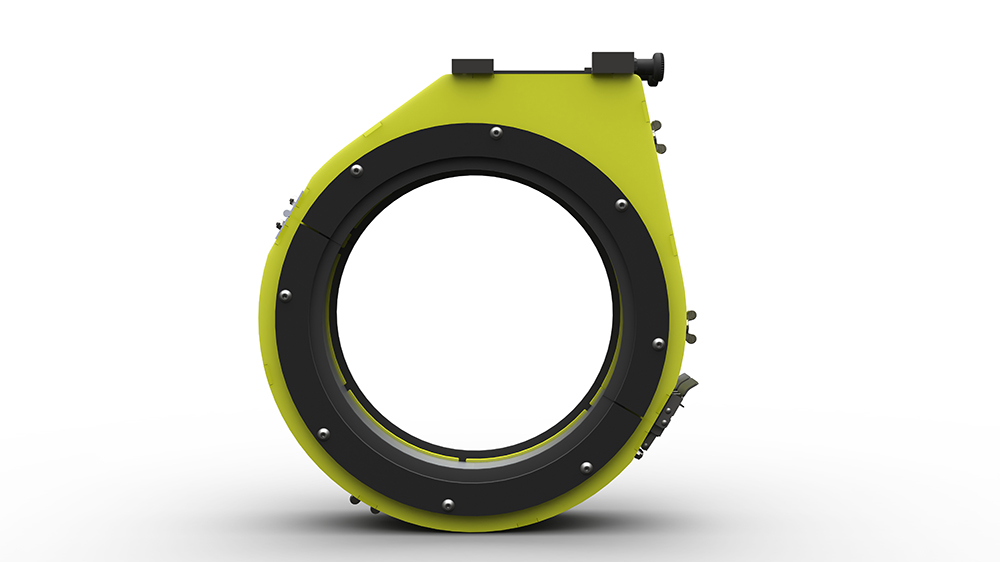

The tools:

Instead of building scaffolds or erecting sheeting, the team used Pinovo tools directly via rope access. All spent abrasive was recovered instantly, and no dust or particles were released into the environment.

The result: 60% fewer man-hours. Zero environmental impact.

The man-hours required for a typical defect were documented and benchmarked against the conventional method. The outcome? A total reduction of 60% in labour time across the 15 defects evaluated.

| Task | Conventional (hrs) | Pinovo (hrs) |

|---|---|---|

| Equipment setup | 6 | 9 |

| Scaffold erection | 21 | 0 |

| Masking/sheeting | 18 | 0 |

| Washdown | 3 | 3 |

| Surface preparation | 12 | 16 |

| Abrasive clean-up | 9 | 0 |

| Coating application | 16 | 16 |

| Removal of masking/sheeting | 4 | 0 |

| Scaffold dismantling | 13 | 0 |

| Total man-hours | 102 | 44 |

“The combination of Pinovo and rope access improved the efficiency of the FM team significantly and eliminated dust and spills to the environment.”

— Mark Smith, Fabric Maintenance & Integrity Coordinator, Repsol Sinopec UK

See the system in action on your site

Pinovo is not just a tool, it’s a smarter way to handle FM in offshore, ATEX, and high-risk environments. No dust. No scaffolding. No shutdowns. But the real power lies in how your team uses it.

That’s why we offer hands-on Pinovo training and onboarding, tailored to your site conditions and team structure. From rope access teams to coating inspectors: we train your people to get it right the first time.