Case Study: REV Ocean – dust-free blasting for the world’s largest Yacht

The REV Ocean is no ordinary vessel. At 194.9 meters, it is the largest yacht in the world – a groundbreaking combination of luxury superyacht and state-of-the-art research platform. Designed by Espen Øino and funded by Norwegian billionaire Kjell Inge Røkke, the yacht is equipped with a moonpool, advanced research labs, a deep-diving submersible, a remotely operated vehicle (ROV), and even a helicopter. Its mission: to push the boundaries of ocean research and environmental discovery, while also serving as a high-end charter vessel.

Transforming a vessel of this scale and prestige at Damen Ship Repair Vlissingen required extensive blasting and surface preparation. Flat sections, weld seams, beams, delicate window frames, swimming pool edges, internal pipe sections, deck plates and the bow all needed to be prepared for new high-performance coatings. Strict coating requirements applied: at least SA 2.5 cleanliness and 75 microns surface profile.

The challenge:

- Protect delicate details such as window frames without damage.

- Prevent environmental pollution, in line with REV Ocean’s ecological mission.

- Work efficiently in parallel with other operations during the yacht’s multi-year upgrade.

- Guarantee top-quality standards, meeting or exceeding coating requirements.

Solution

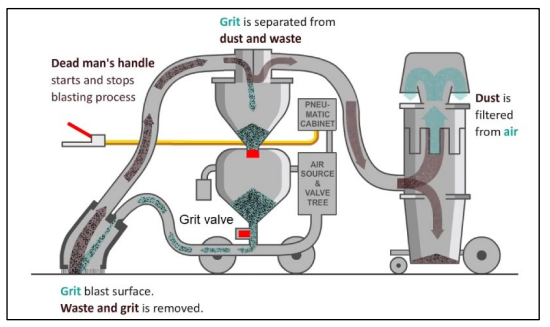

Pinovo introduced its dust-free blasting technology, eliminating the release of grit and paint microplastics into the environment. Together with partner Den Breejen, trained by Pinovo, the blasting was executed safely, sustainably, and in full compliance with coating standards.

Because Pinovo’s method contains all dust and debris, work could continue in parallel with other repair and outfitting activities on board – an enormous time and cost advantage for a project of this magnitude.

Work performed & tools used

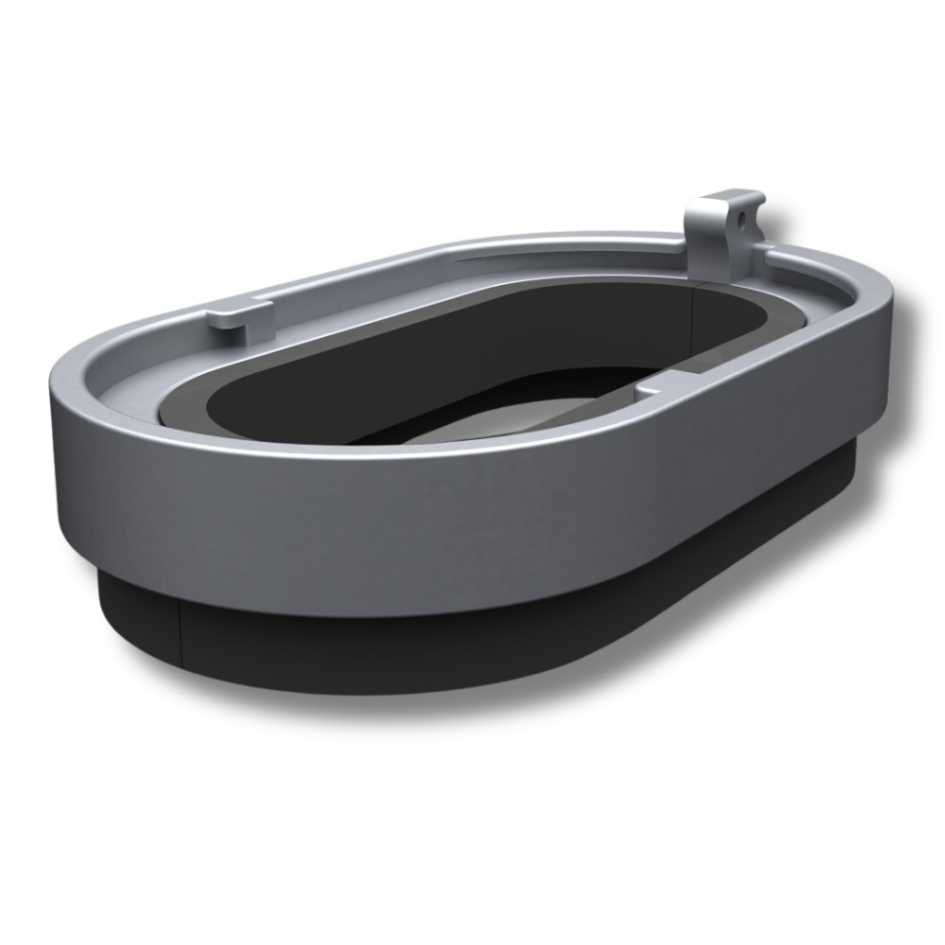

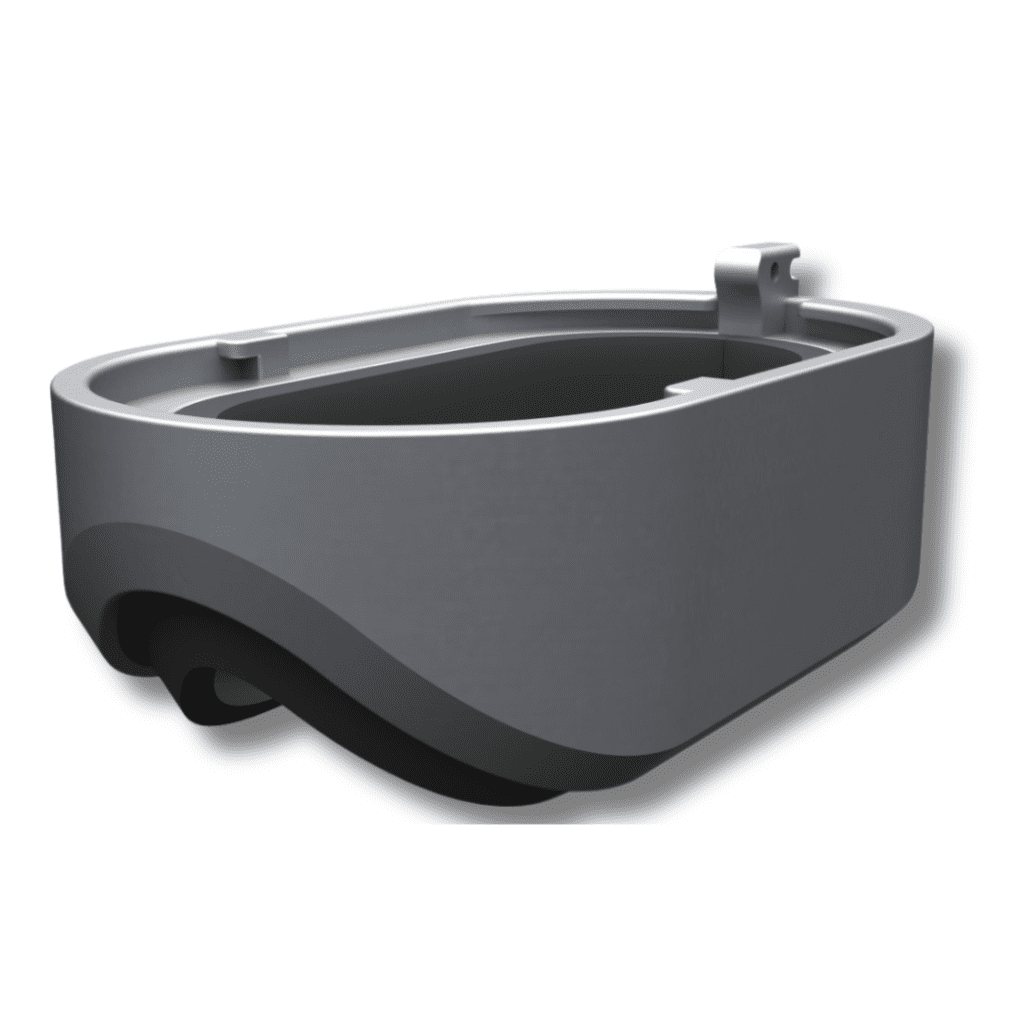

To address the yacht’s complex geometries, multiple Pinovo tools and adapters were deployed:

- Window frames: PiConnect with Angled Adapter for precision blasting around sensitive glass areas.

- Beams: PiConnect with Flat Adapter.

- Swimming pool edge: PiConnect with Edge and Flat Adapters.

- Internal pipe sections: PiHab Flat with magnetic bags for dust-free blasting.

- Deck plates and bow: Prepared with the PiWalk before Belzona bonding.

Pinovo easily surpassed requirements, achieving up to SA 3 (white metal) and 110 microns roughness.

Results & impact

By using Pinovo, blasting on the REV Ocean was carried out safely, efficiently, and without environmental damage. Operators worked in a clean, dust-free environment, while Damen Ship Repair Vlissingen could continue other upgrade activities simultaneously.

This project showcases how Pinovo enables both top-quality coating preparation and sustainable operations. According to Environmental Action (2022), paint accounts for up to 1.9 million tonnes of microplastics each year – more than textiles, tyres, or pellets. Pinovo’s solution directly prevents such leakage at the source.

The REV Ocean fights for cleaner seas, and Pinovo ensures no new paint pollution is added in the process. Together, they represent a new standard for sustainable ship repair and ocean stewardship.

Want to see how dust-free blasting can keep your project on schedule and microplastic-free? Contact Pinovo for a demo and technical advice.