Offshore applications with Pinovo

Offshore maintenance isn’t just challenging. It’s a high-stakes game. Every hour of downtime is costly, and safety is non-negotiable. When flare stacks, risers, or pipelines need surface preparation, traditional blasting methods are risky and logistically complex. Dust, debris, and the need for containment can bring operations to a halt.

Pinovo is different. Smarter, cleaner, safer surface preparation at sea

We offer a high-end, vacuum-based blasting system that’s engineered for offshore environments. Safe in ATEX zones, compatible with rope access, and fully enclosed. Pinovo helps you work smarter, cleaner, and safer.

Let’s upgrade your offshore maintenance. Book a custom meeting with Wiebe.

Your offshore challenges: corrosion, access and safety

Offshore assets face extreme environments and limited accessibility:

- Constant exposure to saltwater leads to corrosion.

- Flare stacks and risers require rope access.

- Explosive atmospheres demand ATEX Zone 1-compliant tools.

- Traditional methods require scaffolding, tenting and containment.

Pinovo eliminates these barriers with safe, efficient and mobile blasting units.offering a clean, closed-circuit blasting system that can be deployed where others fail.

Call, email or plan your route

Why Pinovo sets the standard in offshore blasting

- Fully enclosed, dust-free blasting

- ATEX certified for Zone 1 use

- No contamination of the sea or air

- Safe for rope access teams – low-pressure blasting prevents blowback

- Lightweight, modular system: deployable with 40m hose, no scaffolding

- Ideal surface prep for high-performance coatings

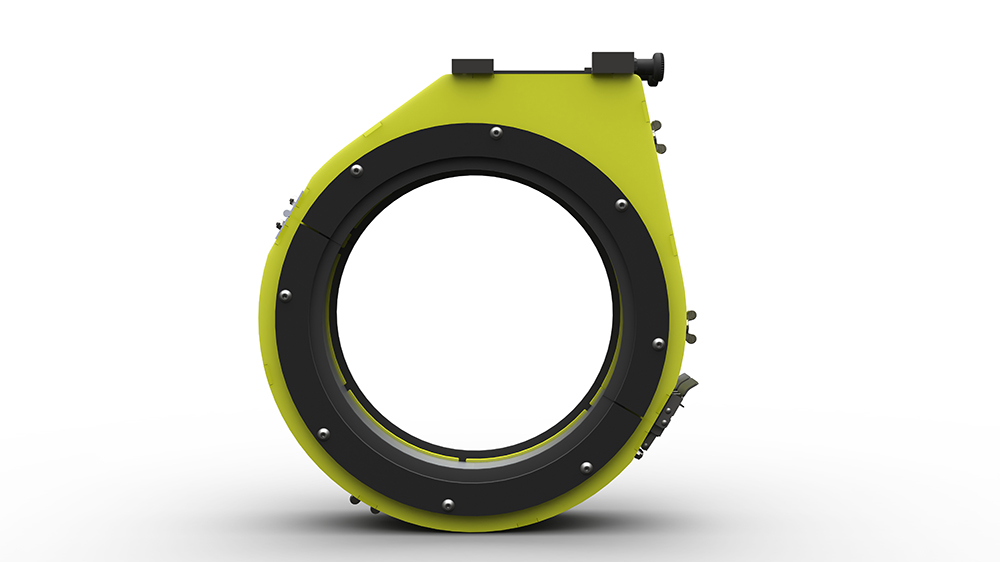

The Pinovo offshore toolset

- PiConnect: Core blasting module with hose and dust separation

- PiWalk: For flat surfaces like deck plates

- PiHab: Lightweight dust and air management unit (perfect for rope access)

- PicoPipe: External pipeline surface cleaning tool

Offshore applications: where Pinovo delivers

1. Flare stack surface preparation

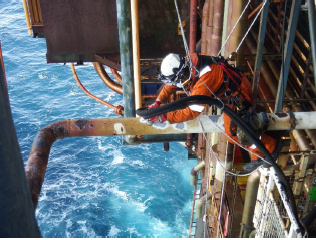

- Rope access only: height, danger zone

- No dust, no sparks, no containment required

- Operate while flare is offline without shutting down other systems

2. Riser pipes & vertical structures

- Pinovo tools are ideal for confined vertical operations

- Easily lifted and operated by rope access teams

- Safe for use in salt-laden, windy, humid conditions

3. Deck plates, walkways & heli decks

- Prepare for anti-slip or corrosion-resistant coatings

- Minimal disruption to offshore operations

- Ideal for localized repair zones

4. Offloading areas

- Often corroded due to exposure to seawater and cargo

- Prepare for coating reapplication without stopping loading operations

5. Pipelines (external)

- PicoPipe enables thorough, contained cleaning of pipe interiors

- External blasting also possible with vacuum containment

Facing similar offshore maintenance challenges? Contact our team for expert advice.

Pinovo & rope access: built for vertical precision

Our entire system is designed to go where traditional blasting can’t:

- Tools weigh less than traditional UHP or grit systems

- PiHab and PiConnect can be lifted and operated by a two-person rope access team

- Safe air flow and dust recovery even at height

- Complies with international rope access safety standards

How Pinovo works offshore: step-by-step

1. Tool setup – light, modular units ready in minutes

2. Vacuum blasting – surface cleaned without dust emission

3. Waste collection – debris is stored in sealed container (no environmental release)

4. Coating ready – substrate is now clean, dry, and ideal for bonding

Curious how others use Pinovo?

Browse our case studies and discover how industry leaders like Shell, Equinor and others use our technology to stay compliant, reduce downtime and protect their people. Read more: Dust-free surface preparation at height on Shell’s Nelson platform

Technical and safety certifications

- ATEX Certification: For use in explosive atmospheres (Zone 1)

- No open grit, no release of particulates

- Training and documentation available

Partnering with contractors & distributors

We don’t just sell tools. We help implement solutions:

- Collaboration with local experts

- On-site training for contractors (including rope access teams)

- Integrated repair strategies: Pinovo + coating = total solution

Demo, training & technical support

We support you at every step:

- Live or remote demos for you or your client

- Rope access training with a focus on real offshore conditions

- Pre-project planning and support from Pinovo technical specialists

Let’s design your offshore surface solution. Book an online consultation today.