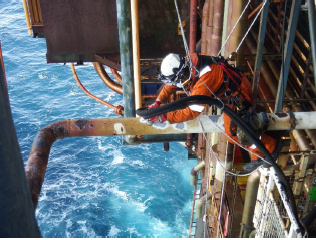

Dust-free surface preparation at height on a offshore platform

Offshore pipe blasting without shutdown, contamination or safety risks? That’s exactly what Shell achieved with the Pinovo PiSys 100 on a offshore platform

Challenge: Corroded pipework in a sensitive offshore environment

They faced a major maintenance challenge: 125 metres of 6” diameter pipework with heavy corrosion and degraded coatings needed urgent attention. Located on the outboard side of the cellar deck across modules C1 to C4, the pipework was not only difficult to access—it was also surrounded by sensitive equipment and live operations.

Using traditional open grit blasting would have required:

- Full encapsulation and extensive masking

- Shutdowns of surrounding systems

- Significant HSE measures

- Over 1,500 man hours of work

Shell needed a cleaner, safer, and more efficient method. That’s where the Pinovo PiSys 100 closed-loop blasting system came in.

Want to reduce costs without compromising safety?Schedule a consultation with Wiebe and discover how dust-free blasting with Pinovo can accelerate your offshore maintenance projects.

Solution: Rope access blasting with the Pi-connect tool

Instead of scaffolding, rope access was used for nearly all blasting activities. The PiSys 100, combined with the Pi-connect tool and the 6” adapter, enabled spot and sweep blasting of the corroded surfaces to SA 2.5 with an anchor profile of 70–80 µm—without producing dust, sparks, or secondary waste.

Key benefits observed:

- 809 man hours saved compared to traditional blasting

- No encapsulation needed

- Zero media clean-up and no contamination

- Minimal PPE required (no full air helmet needed)

- No access restrictions for surrounding personnel

The job was executed while the pipe remained in service, under the live line blasting procedure.

Results: Cost savings, safety gains and proven quality

They reported a significantly safer and faster project:

- Clear and easy operation

- No breakdowns or downtime

- High-quality blast profile

- Fast tool setup and shift handover

Thanks to the PiSys 100 and Pi-connect tool, the fabric maintenance was completed to coating spec using ACOTEC HUMIDUR ME and TC at 400 µm—extending the pipe’s life expectancy up to end of field life (EOFL).

“The PINOVO closed loop blasting system has clearly demonstrated that it is a cost efficient technology to conduct Fabric Maintenace. Not only does it provide the optimum surface profile and cleanliness available to extend the lifecycle of a coating it has demonstrable HSE benefits, not only for the blasting technician but for the personnel on the asset.”

— Shell Fabric Maintenance Coordinator, Nelson Asset

Experience it yourself

Want to see how Pinovo can reduce costs and risks in your offshore projects?

Schedule an appointment?